Ceramic And Porcelain Tile Manufacturing

Porcelain tile has been crafted across the globe for thousands of years. Today, updates in design and manufacturing technologies have changed porcelain tile dramatically, making it more durable, easy-to-clean, and versatile than it has ever been. Porcelain is made from very fine clay that is fired at high temperatures to remove more moisture from the tile resulting in a hard and dense tile. The density of porcelain tile makes it ideal for high traffic areas in homes and most commercial properties.

How Porcelain Tile is Made

The Magic Begins

Water and raw materials mix together until a sand-like consistency is reached. Recipes vary slightly however feldspar, clay, silica sand and other materials are included in the mixture.

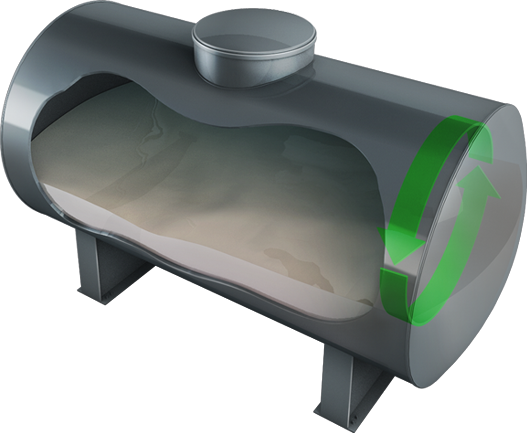

Getting the Perfect Consistency

In this next step, a spray dryer removes the excess moisture from the mixture until the perfect consistency is reached before the mixture is moved into a press.

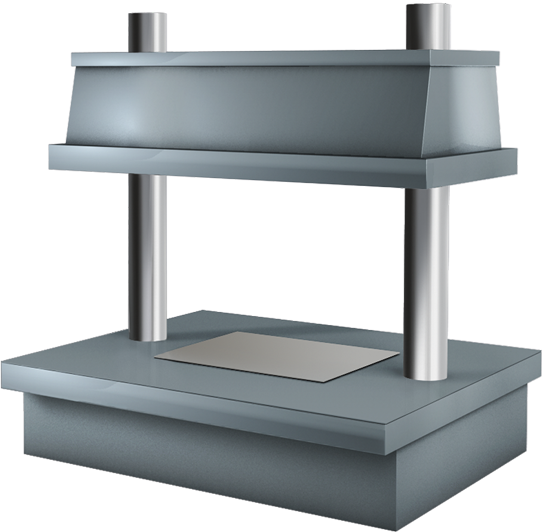

Creating the Tile

Now, the porcelain mixture is pressed to form the tile. Each size and shape of available porcelain tiles use a special punch to create the body of the tile, called Greenware.

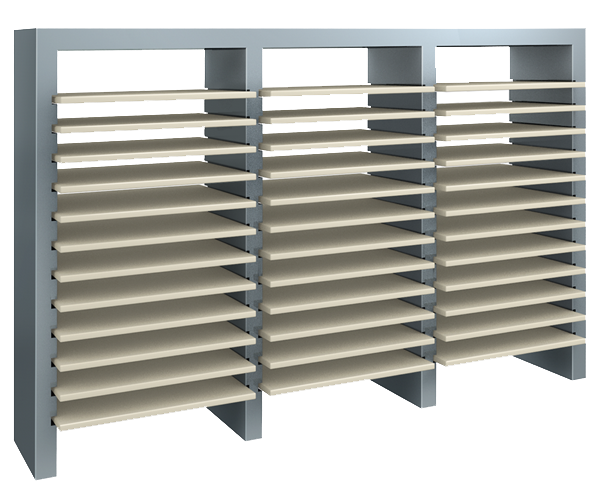

Curing Begins

Greenware is the term used for tiles that have not been glazed or fired. Prior to that step, the raw materials are placed in a dryer to remove moisture, readying the tiles for the next step.

Printing & Glazing

After the tiles have dried, the next step is to add the pattern and colors using a state-of-the-art inkjet printer. After the pattern is applied, the glaze is applied to protect the tiles.

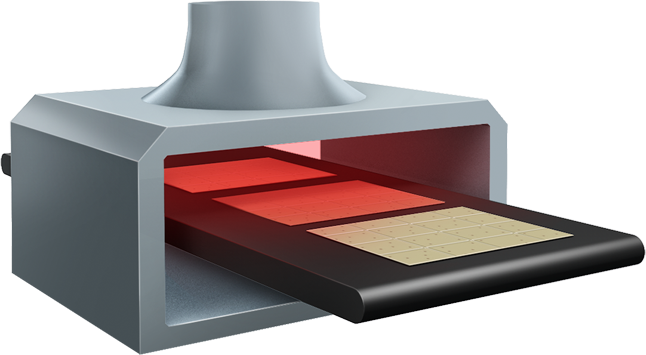

Into the Kiln

The tiles are then fired in a Tunnel Kiln or Roller-Hearth Kiln at 2300℉ and 2455℉ for longer periods of time to remove all the moisture in the tiles. Most factories have a minimum of 2 Roller-Hearth Kilns operating at the same time 24hrs a day, 7 days a week.